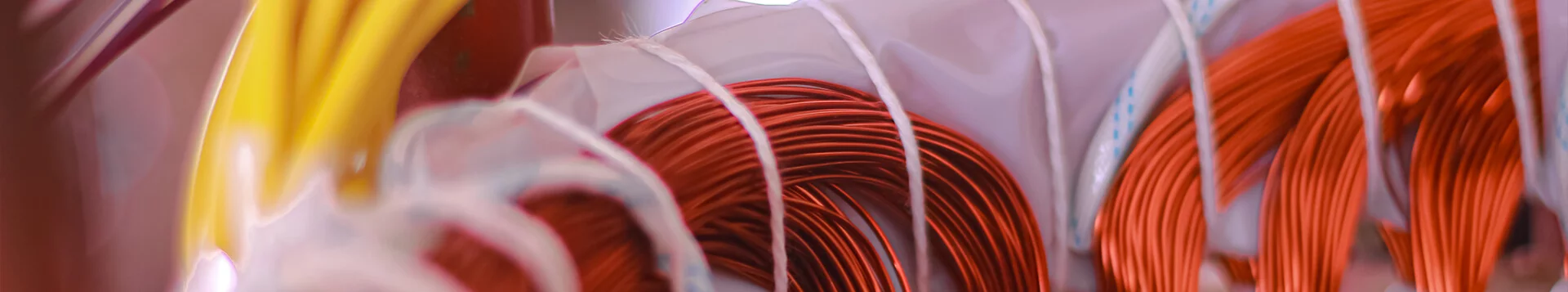

Fiberglass sleeving

For different sizes, current stock or more information, please contact us at: +359888888094; elektrabg@abv.bg

Description

Fiberglass sleeving is a hollow cylinder made of braided fiberglass yarn. The fiberglass tube is produced by braiding the glass thread into the required pipe size. Unlike other types of sleevings, the heat resistant sleeve has no electrical protection. However, the material offers excellent fire protection and higher heat resistance, compared to other types of sleevings. There are 2 types of fiberglass sleeves: thin-walled and thick-walled. In addition to their different internal diameter, the two types of sleeving also differ in their wall thicknesses.

Areas of application

- mechanical and thermal protection of cables

- transformers

- ovens

- drying channels

- household stoves

- electric appliances

- elements subjected to constant high temperatures

- engine exhaust manifolds

- exhaust systems

- others

Stock

| Ф (mm) | Wall thickness (mm) | Length (m) | Type |

| 5 | ≈0.40 | upon request | Roll |

| 10 | ≈0.50 | 20 | Roll |

| 20 | ≈2.5 | 20 | Roll |

| 30 | ≈3 | 20 | Roll |

| 40 | ≈4 | 20 | Roll |

Specifications

| Properties | Value |

| Working temperature | -60°С ÷ +450°С |

| Maximum short-term temperature | 550°С |

| Flammability | non-flamable |

| Water absorption | NONE |

| Flexibility | Very flexible |

| Good resistance to welding | YES |

| Resistance to transformer oils | According to UTEC 93641 |

| Dielectric strength | 0,4kV ÷ 0.8kV |

| Compatibility with impregnation varnishes | YES |