Polyethylene (PE) fall into 3 types:

- PE HD/PE 300 – high density

- PE HMW/PE 500 – high molecular with a molecular weight greater than 500 thousand g/mol

- PE UHMW/PE 1000 – ultra high molecular with a molecular weight greater than 3 million g/mol

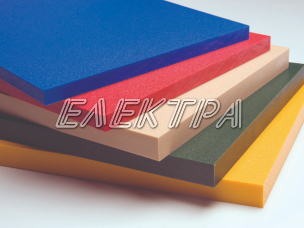

Polyethylene HDPE

Polyethylene PE is a thermoplastic material and is one of the standard plastics which is most commonly used. HDPE is used in a wide range of different sectors. Polyethylene HDPE is not strongly affected by scratches and has excellent electrical insulating properties. PE has extremely low water absorption and excellent chemical resistance. Polyethylene has long life, is easy to process and has good mechanical properties. Polyethylene also has good welding properties, are resistant to chemicals and has a high density but low weight. HDPE absorbs practically no moisture and is physiologically safe in accordance with EU and FDA for contact with food, similar to the POM-C Polyacetal.

Some of the advantages of PE are:

- Excellent vibration and noise absorption

- Physiologically safe

- Suitable for contact with food (FDA)

- Good mechanical properties

- Good processability

- Excellent welding and processing properties

- Good chemical resistance

- Excellent slip properties

- Good machinability

- Low weight

- Very low water absorption: <0.01%

- Dimensional preservation during processing

- High corrosion resistance