Phenolic cotton cloth laminated materials

Phenolic cotton cloth laminated materials are layered materials obtained by hot pressing two or more layers of cotton fabric impregnated with synthetic thermoset resins. The phenolic cotton laminated sheets and rods have excellent electrical insulation properties. Phenolic laminates have good heat resistance. Because cotton fabric is included in the composition of phenolic cotton cloth laminates, they have high crushing strength and increased flexibility. These materials are easy to machine by drilling, slotting and forging. The phenolic cotton laminated sheets, rods and tubes have very good mechanical properties and absorbs vibrations well. Phenolic cotton laminated materials are the traditional alternative to technical plastics.

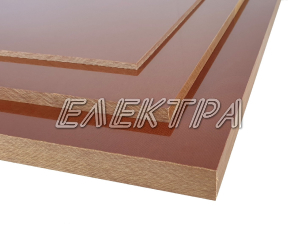

Textolite

Textolite or phenolic cotton cloth laminated material is a durable structural material composed of textile fabric saturated with phenolic or epoxy resin. This production method provides textolite with high strength and resistance, making it ideal for various industrial applications where reliability and longevity are required.

What is textolite made of? Textolite is produced by layering textile fabric impregnated with resin and then subjecting it to high temperature and pressure. This combination ensures excellent mechanical and electrical insulation properties. As a result, textolite becomes strong, wear-resistant, and suitable for high-load industrial environments.

Key applications and advantages of textolite:

- Textolite rods: Used to manufacture mechanical parts such as bushings, pistons, and gears that need to withstand high loads and mechanical friction. They are popular in mechanical engineering due to their durability and long service life.

- Textolite sheets: Suitable for constructing insulation and mechanical components used in electrical engineering, including distribution panels, bases, and boards.

- Electrical insulation properties: An exceptional electrical insulator, often used for panels and bases in electrical equipment. These properties make textolite a preferred choice for components requiring high dielectric strength.

- Heat resistance: Retains its properties at high temperatures, making it suitable for applications in high-heat environments like electric motors and transformers.

Paper laminates or Cloth laminates? When choosing between getinax and textolite, it’s essential to understand the characteristics of each. Getinax is made from paper impregnated with phenolic resin and is a more cost-effective option with limited durability. It is excellent for lighter applications such as insulation boards and printed circuit boards in the electronics industry. Textolit, on the other hand, is stronger and more durable, preferred for complex constructions that require high strength and mechanical stability.

Advantages of textolite:

- High mechanical strength and rigidity: Suitable for applications requiring stability under heavy loads.

- Wear resistance and long service life: Ensures reliability in long-term projects.

- Resistance to chemicals and moisture: Can be used in environments with aggressive substances without losing its properties.

- Easy processing: Can be cut, ground, and machined, making it convenient for various manufacturing needs.

Why choose textolite? Textolite is preferred by engineers and technicians due to its combination of strength and excellent insulation properties. Whether it’s for mechanical engineering, electrical engineering, or the automotive industry, textolit is a proven choice for reliability and long service life.

Discover high-quality textolite sheets and rods from Electra and rely on our expertise and support to help you choose the right material for your needs.